It’s the everyday things that interest me: Replacing an offside brake light on a Punto

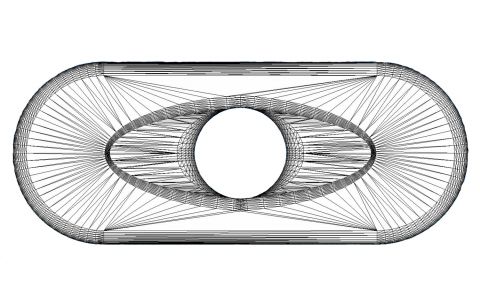

I have never been very interested in cars and I’ve had a few, always second hand and I’ve always done some of the maintenance myself. The H reg Nissan Sunny I had was a great motor which when I got it was 10 years old with 12,000 miles on the clock. It was a great car and because of its age pretty simple, unfortunately it gave up in a major way at a very inconvenient moment and was thus collected by the scrap man who gave me £30 for it. The new (to us) T registration Punto is a different kettle of fish entirely I suddenly feel pretty inept at anything to do with its maintenance and he who deals with the car has now taken over. As it’s a more modern car much more is hidden away in odd and inaccessible places behind plastic panels. To change a rear brake light bulb was more involved than it needed to be (see the images). Is this about styling, about manufacturing processes or about encouraging us to pay for everything to be done?

Car maintenance is becoming less of a DIY activityand more of a service we need to purchase. This puts the emphasis on us to earn the money to pay for someone to carry out the job. Gone are the days of my friend Cath’s dad painting (yes that’s painting) their car every year or so with a brush and tin of gloss paint (and I can admit to that myself also – but I used a roller) but things like that bring a smile to your face, the image of someone painting a car with a brush. The alternative can be compared to wondering how much the coloured coded bumper on your new vehicle is going to cost to replace when it gets a knock.

So is the complicated bulb change about encouraging us to pay for services rather than doing it ourselves? It’s naïve to think its accidental – I’m thinking back to Derek’s information about design intention. I am sure someone at Fiat had the task of carrying out routine car maintenance jobs and timing them before the car went into mass production. What encourages me is the inclusion of a small kit of tools provided with the car which allow for the panelling to be undone, but who did the manufacturer imagine would be doing the undoing.

Progress through planned obsolescence

The book I ordered through the library has arrived. The Waste Makers by Vance Packard. Even though I am fully occupied by long lists of preparations for the exhibition I couldn’t resist a quick look at the book. It’s very pertinent – ahead of its time in many ways, he gives the following definitions:

Obsolescence of Junction: in this situation an existing product becomes outmoded when a product is introduced that performs the function better

Obsolescence of quality: Here, when it is planned, a product breaks down or wears out at a given time, usually not too distant.

Obsolescence of desirability: in this situation a product which is still sound in terms of quality or performance becomes ‘worn out’ in our minds because a styling or other change makes it less desirable (1).

These things are familiar to anyone with an awareness of consumerism.

I think a fair amount of it will be familiar given the contemporary writings and debates on sustainability / industrial design but it will be important to remember the time and context in which is was written – 1960’s America.

1. Vance Packard The Waste Makers(London, Longmans 1960) p. 55

Exhibition

The Potential Object is an exhibition of work produced during my digital making residency. With investigations focused on the relationships between my own video practice, Computer Aided Design and Additive Layer Manufacturing the exhibition will show selected works including photography, video, drawing and objects.

11th & 12th September 2010 – Open 10am to 3pm. In addition to the exhibition, tours of Hethel Engineering Centre will be available as part of Hertitage Open Days. Free & no booking required.

The exhibition continues until 17th December 2010 open Monday to Friday – By Appointment only. Please contact [email protected] Tel: 01953 859100 to make an appointment.

Hethel Engineering Centre, Chapman Way, Hethel, Norwich, NR14 8FB, www.hethelcentre.com

Workshop of the World

I watched the film Manufactured Landscapes last night http://www.edwardburtynsky.com which was inspiring, depressing and slow moving. Burtynsky adopts a ‘neutral’ position to the subjects he photographs, neither condoning or condeming the industries he is documenting rather leaving them open to audiences to discuss and debate. There is an overwhelming feeling of foreboding as e-waste (computers etc) are disassembled without regard for the health of the workers or the environment. The film repeatedly uses shots of the hands at work, the body presented as a fragmented object. Presumably the rest of the body is in a rather fixed posture. There were similar shots of the hands in the British documentaries I have been watching from the 1930’s and 1940’s. (see yesterdays post).

I remember seeing one of Burtynsky’s images years back in Flowers East Gallery of chicken processing in China and I have never forgotten it. The production in those images is on such an immense scale it totally contrasts to everything I have seen at Hethel, which is by its nature (research and development) smaller and more detailed. I find repeatedly when people discuss first impressions of factories it’s the noise that’s often mentioned, how loud the machines are. What I notice most in the RP room at Hethel is not only the lack of noise but also the heat that is generated by the machines working away.

I cannot help thinking about our history as the ‘workshop of the world’ describing our outputs in the 1850’s onwards. Christine MacLeod puts historical production into a global context and says “No country was as specialised as Britain in manufacturing in 1901”. (1). Contrast this with a recent Guardian article where Ian Jack explored British Industry, he states

“The British economy is to be ‘rebranded’. The country – ‘UK plc’ will remember the source of its original prosperity and turn again to making things…..The manufacture and export of goods suddenly appeal as a way out of recession to a political class that has largely ignored industry for several decades. The phrase industrial strategy still evokes cold sweat memories of British Leyland, bad cars and bottomless pits”. (2)

With this talk of bad cars I recall something Helen Sloan said to me on Monday when we met up to catch up on the project. She mentioned the phrase ‘The Friday afternoon car’ which I had not heard before. It is used to describe substandard goods and lack of attention to detail with the implication being that on Friday afternoon the ‘workers’ would be winding down for the weekend and as such productivity would be less focused and lower. With how we produce goods now, I wonder if the Friday afternoon dip is less likely to be evident as factories work 24/7 on shift patterns, so the beginning and end of the week is unfixed. We have also moved towards being machine minders, where computerised systems monitor production quality. I remember Derek explaining that the CNC machines at Hethel monitor the force/power it takes to drill a part, as the force increases the implications the tool is becoming blunt and will need changing. I’m assuming a warning notice is displayed to the operator to take action to rectify the problem.

1.Christine MacLeod Workshop of the world Located online at: http://www.bbc.co.uk/history/trail/victorian_britain/industry_invention/britain_workshop_world_01.shtml Accessed 6th August 2010.

2. Ian Jack Filling the Vacuum The Guardian on Saturday 24 July 2010 p. 26

Integration of theory and practice

I research and read – a fair amount – it helps my ideas develop. Historical research is of particular interest but also contemporary accounts and investigations about work and the changing nature of work particularly in relation to production.

I have recently purchased Land of Promise The British Documentary Movement 1930 – 1950. Although I considered my main focus to be situated in the post war era in terms of research, these 40 films (which I have only just begun to view) offer a valuable opportunity to see what British industry looked like in this era and to hear the accompanying commentary. Industry appears repeatedly in this group of films over a 20 years period, from pre-war through the war years, to the post war era.

In the introduction to the accompanying booklet Patrick Russell states:

“We may like to think of our own era as uniquely exciting, fast paced, unpredictable. Yet the 1930’s and 1940’s were truly tumultuous decades. In Britain they encompassed depression and partial recovery, scientific and cultural innovation, a world war threatening its very existence, then huge social reform permanently changing it”.(1)

These films include documentaries of pre-war activities such as Workers and jobs (1935) where the labour exchange processes are explored. The Transfer of skill from 1940 depicts the skilled craftsmen (and it is men who are the focus of this film) as they re-invent their skills in jewellery and watch making to produce gauges and parts for weapons for the war effort. In the essay which accompanies this film, also by Patrick Russell, he states “…the close association of manufacturing industry with national identity in both peace and war, and the importance of the skills and efforts of human beings (as much as machines) to both”. (2). In the post war era it was the section on Motion study in the Britain Can Make It (1946) efficiency and ergonomics come into play with beautiful shots of hands at work.

To accompany the exhibition of digital making next year I have a series of film screening in mind which could if its possible include some of these documentary pieces in addition to Manufactured Landscapes (Jennifer Baichwal’s film about Edward Burtynsky photography), which I have bought but not had a chance to watch yet.

1. British Film Institute Land of Promise The British Documentary Movement 1930 – 1950 Various directors and titles – see http://filmstore.bfi.org.uk/acatalog/info_8457.html

2. ibid p33